2020 Robot Overview (Tea3PO)¶

Design Priorities¶

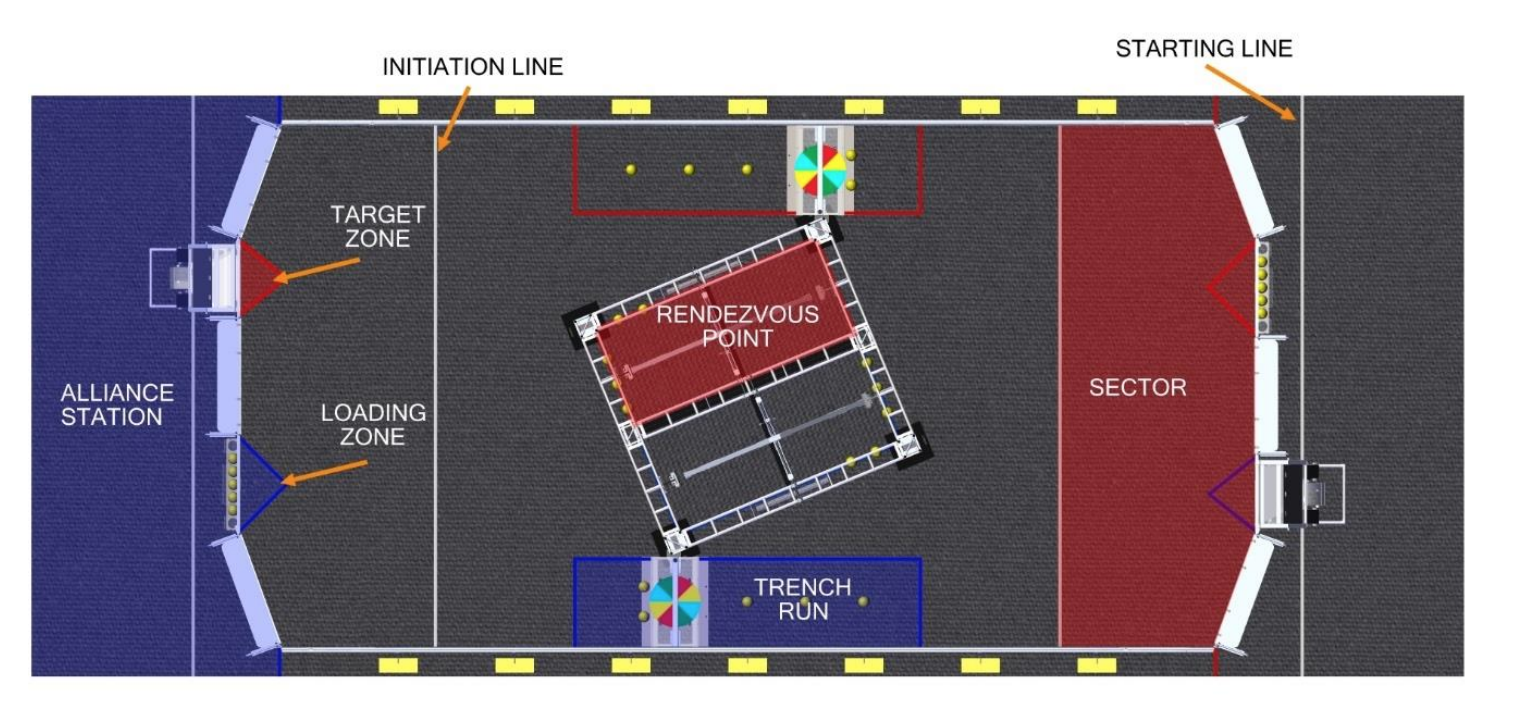

Goal¶

Make it to playoffs at a regional level.

Expected Capabilities¶

Here are our expected capabilities for alliance robots during the playoffs. Our robot is designed around being a first pick.

| Ability | Top 4 Alliance Captain | First Pick | Second Pick |

|---|---|---|---|

| Climbing | Climb power switch with leveling/even out capability/buddy climb | Climb power switch and stay there | Climb power switch and stay there |

| Spin/Rotational Control | Spin control panel with both positional and rotational control | Spin control panel with rotational control | |

| Scoring Consistency | Score high goal nearly every time | Score high goal consistently | Play defense or score on low goal |

| Scoring Quantity | Score three or more balls in high goal during autonomous period | Score three balls in high goal during autonomous period | Score on low goal during autonomous |

| Number of Balls Stored | Pick up and store five balls at a time | Pick up and store five balls at a time | |

| Floor Intake | Intake balls from the floor | Intake balls from the floor | |

| Passable Through Trench | Be able to go through the trench | Preferably go through trench |

Tea3PO's Design¶

Climbing Mechanism¶

The climbing mechanism is a top priority for our robot.

- The endgame climb is the highest single-action scoring opportunity in a match.

- To get the endgame ranking point, each alliance needs a minimum of two robots hanging on the shield generator.

No Control Panel Mechanism¶

A spinner mechanism for the Control Panel was of low priority

- only beneficial for gaining RP, which isn’t important in playoffs.

- focused more on designing the shooter

High Goal Shooter¶

We chose to design a shooter mechanism that could score high-goal as quickly as possible.

- Rule G11 in Section 7.2.3 of the 2020 game manual states that any robot within it’s target scoring zone is protected from other robots.

- Because of this rule we decided to create a shooter optimized for shooting within the target zone.

One of our prototype shooters

Autonomous Shooting¶

We decided that it was extremely valuable to take advantage of the autonomous double point scoring period.

- At the start of each match, each robot can hold up to three balls.

Ground Intake¶

Initially, we put a ground intake as a lower priority, but later in the season it was determined that a ground intake gave us significant strategic advantages.

- would allow us to intake balls anywhere on the field.

Mechanisms of the Robot¶

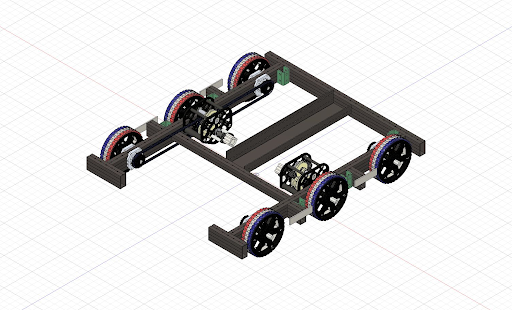

Drivetrain¶

Chassis and Wheel¶

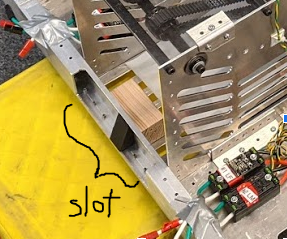

The robot has a 31" x 28" West Coast drive base with six 6" VEXpro traction wheels.

- 6" wheels give us sufficient ground clearance over the 1" metal tubes in the rendezvous point

- We added a 1/16" center drop to decrease the skid in our front and back wheels to allow for smoother pivoting.

- To reduce the distance that the power cells have to travel while maintaining chassis stability, we cut a 7" section on our front rail that allows for power cells to pass into the robot.

The cut allows for power cells to be taken into the robot while still maintaining contact with either the ground intake and conveyor belt at all times without having an open chassis (shown below).

Unlike closed chassis bots, open chassis bots do not require a ball to be raised above the front chassis frame.

Unlike closed chassis bots, open chassis bots do not require a ball to be raised above the front chassis frame.

Drive Gearboxes¶

Each side of the drivetrain is driven by a WCP SS gearbox with two falcon 550 motors geared at a 10.42-1 ratio. This helps achieve the robot’s max speed of around 13 ft/s.

Shooter¶

Prototypes¶

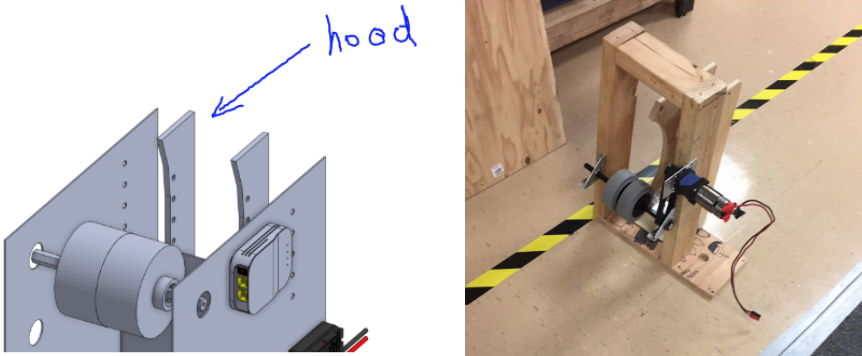

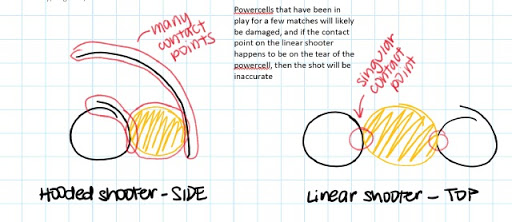

We had two main prototypes: a hooded shooter and a linear shooter.

- The linear shooter used two wheels on each side, and created relatively consistent and accurate shots. The hooded shooter also resulted in similar results.

- Both proved to have enough power to achieve the goals that we had set.

We decided to go with the hooded shooter, as the hood increased the number of contact points between the mechanism and the power cell.

We were concerned that any variation on the power cells, such as a tear or hole in the power cell, could drastically decrease the accuracy of our shots.

Final Design¶

The final shooter design consists of...

- two ¼" thick polycarbonate rails with arcs

- 3D printed hood attaches to the rails to control the release angle and follow the contour of the shooter wheel

- a 3lb Neoprene drive roller (shooter wheel)

- driven by 2 NEO motors at a 1:1 ratio

Shooting Demonstration

Accumulator¶

Prototypes¶

Hopper vs Conveyor vs Ramp

The Ramp¶

We tested a shallow, gravity driven ramp, but decided that the speed at which the power cells feed into the shooter would be slower than we wanted.

The Hopper¶

Concerns about the hopper’s potential to jam balls led to the conveyor being chosen over it.

The Conveyor (Chosen!)¶

We built a wooden prototype of the conveyor, but found that the single NEO brushless motor wasn’t powerful enough to move the power cells through the system, so we settled for a two motor system.

Final Design: Conveyor¶

The final design is a conveyor that files power cells one by one. The conveyor is broken into two separate sections and has an "L" shape. Each section has a single NEO motor geared similarly to the shooter to minimize energy transfer between the shooter and the balls.

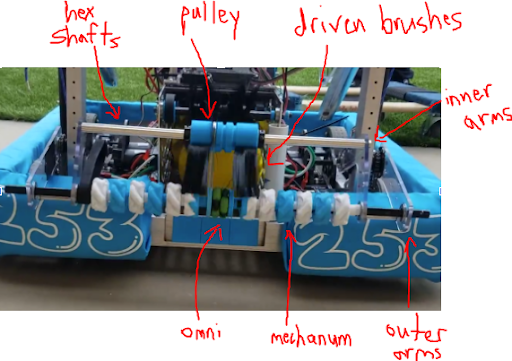

For the horizontal section, brushes are placed inside the conveyor. The conveyor is capable of holding five power cells and accelerating to full speed, allowing all five power cells to exit the conveyor quickly.

- These push balls towards the rear and prevent jamming.

The vertical section consists of a single conveyor with 0.5in compression to move the balls upward into the shooter wheel. This section automatically stores two balls vertically.

- Two photoelectric sensors are located at the top and bottom

- The bottom sensor detects balls and tells the conveyor to run and push balls up one at a time.

- The top sensor is used to keep space between stored balls and shooter wheel

Ground Intake¶

Prototypes¶

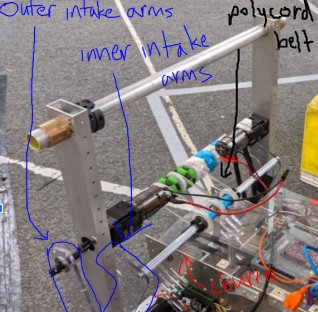

To find the types of the wheels, height of the intake, and distance of the intake from the bumpers, we drove a hex shaft with a drill, varying the wheels and relative distances until we found the combination that would allow the power cells to be rolled up into the chassis.

We realized that because the intake is only actuated by a motor on one side, the other side would not follow and retract into the robot, resulting in one side sinking down, or an asymmetrical intake.

We solved this issue with a set of inner intake arms, connected by a churro shaft.

We also found that the power cells were jamming between the intake and the conveyor. We added driven brushes to the churro support of our intake to help guide the power cells smoothly into the conveyor.

Intake Demonstration

Final Design¶

The final ground intake has…

- Ten 3" mecanum wheels on the intake and one center omni wheel, which center the power cells when they contact the intake.

- One pair of inner and one pair of outer polycarbonate arms, which support the hex shaft running across the front of the robot.

- The retraction is driven by a BAG motor and the spinning of the intake wheels is powered by a 775pro.

- Poly Cord belts run from the driven thunderhex shaft to the churro support, driving pulleys that spin the intake brushes.

Climber¶

Prototypes¶

Telescoping Cascade vs 4-Bar Arm vs One Point Pivot

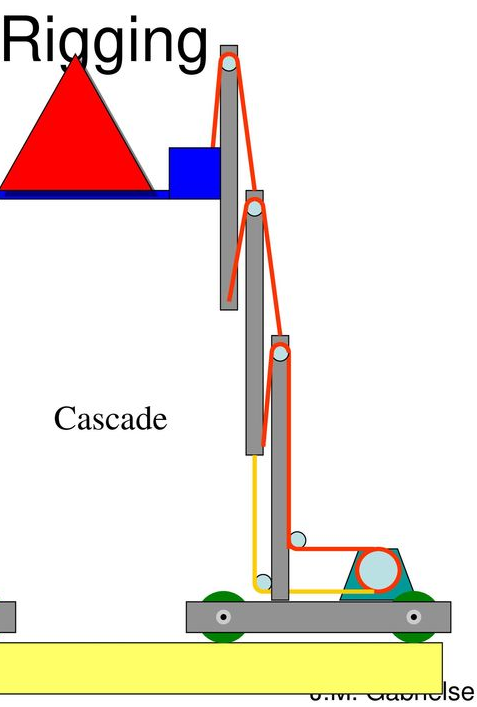

The telescoping cascade was prototyped out of PVC and thin cable. It worked well, but would require us to either sacrifice not being able to fit under the trench, or build at least four stages to reach our target height.

The 4-Bar Arm also worked effectively, but was eliminated for its complexity.

The 4-Bar Arm also worked effectively, but was eliminated for its complexity.

The team settled on the one point pivot arm because it was

- simple

- allowed us to reach our desired height

- achievable by our team

Final Design¶

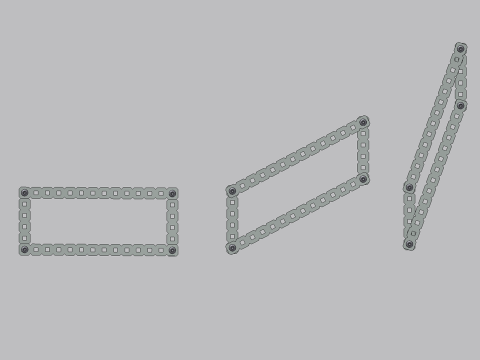

Our final design is a one point pivoting climb with…

- Two vertical support bars, which are mounted at the front of the robot, with two aluminum 1x1 tubes on each side to act as arms.

- The arms are controlled by two 775pro motors, one for each arm.

- Two polycarbonate hooks for extra reach and to attach to the climbing bar.

- The hooks are 22" long, and made of ¼" thick polycarbonate.

- 3D printed bearing carriages allow the hooks to slide up and down the climber arms

To Extend the Arm

- Gas shocks extend the climber arm upwards, and a constant force spring pulls the hooks up.

- A winch rope (paracord) holds the arms down, and when the motors actuate, allowing the winch rope to release, both the climber hooks and the arms are raised and the rope is unwound.

- If needed, bearing carriages will slide the hooks up and down the climber arms.

To Retract the Arm

- At the start of the round, rope connecting the hooks and the motor is wound up in one direction.

- When we want to retract the arm, the motor continues to drive in the same direction, and the winch rope continues turning (in the same direction) and winds itself up again, allowing the arms to both extend out and retract back.